Startup Jedi

We talk to startups and investors, you get the value.

"Startups in maritime logistics are much fewer than in land logistics, so the entry threshold is higher. This is a wonderful opportunity for growth," Ivan Ladan, the CEO of Marine Digital, says. We learned from the team how they develop, what the victory in EMERGE CHALLENGE gave them and who the ideal investor for the startup is.

Startup Jedi

We talk to startups and investors, you get the value.

The state of the maritime logistics market made it obvious to me which niche for a startup to choose. Land logistics has already been almost fully automated and hundreds of companies work in this field because the entry threshold is low.

It is more difficult to automate maritime logistics as the market is divided between a small number of big players, with whom the communication is frustrating because of their large size and conservative views. Maritime laws have been evolving over the centuries and don’t change quickly. Therefore, digitization in maritime logistics is much slower than it is in land logistics.

Industry expertise is also a problem. Driving a truck and carrying cargo on a container ship are very different tasks in terms of complexity. Requirements are much stricter, reporting is more thorough and the cost of a mistake is higher. There’s a lot of special terminology, without which it is simply impossible to communicate with professionals. Consequently, there are very few IT experts in maritime projects.

We see challenges as opportunities in these circumstances. Ships provide world trade and traffic volume increases every year. This is a huge market, and oceans are still blue (i.e. market space is still unknown and untainted by competition).

...

Our main product is Marine Digital FOS (Fuel Optimization System). It allows reducing fleet fuel consumption and provides the most optimal route based on the information about sea state, weather and vessel operational conditions. It consists of equipment that collects and processes data on the vessel, and our software.

Wind, currents, storm, hull fouling and many other factors affect fuel consumption of ships. If all these factors are taken into account, it is possible to build an optimal route and reduce fuel usage.

We are working with several shipping companies on 7 vessels of different types. The more parameters about external and internal factors influencing fuel consumption we can collect on a particular ship, the more accurate the model will be and the more fuel economy will be.

Our goal is to create the best dataset in the industry, allowing achieving savings of 5–12%. Sea weather forecasts often are at odds with reality, and 70% of the market is occupied by old-fashioned ships — data on the operation of their nodes is not recorded. We had to design our own equipment to gather the information we needed.

Based on Nvidia’s solutions, we made a system that collects meteorological information from sensors on the ship and data about the operation of the units. We also collect data about underwater currents, salinity along the ship’s route, and other factors.

Our project became successful after a pivot. A year ago we started to sell another product — the ship automation system. When a ship arrives at a port, it orders a lot of services: towing, mooring, repair, delivery of products etc. Oftentimes the ship is mistreated, high prices are charged, and it is hard to sort out later.

We created an MVP system that could track all these processes and offered the idea to several ports. They liked it, but a very long budgeting cycle didn’t suit us. Ports provide costs straight off for a year, so they could buy our product only next year. The startup can’t wait that long. We had to refocus on the fuel optimization system. We also support the ship automation system, there is demand for it.

...

We have learned that ship owners are willing to pay for products that their companies pay off in less than two years. On this basis, we have set an upper price limit for subscription to our services which depends on the size of the company. For example, for an average ship owner (30–40 ships) we sell FOS for €6,000 per ship per year. The installation of equipment and additional sensors may be carried out by the ship’s engineer independently or can be paid for extra.

As for hardware, we customize it for each client because they have different requests. For example: it is more important for companies in the CIS to stop stealing fuel than to save it. And this is not an easy task — ship fuel (Heavy fuel) is more like crude oil than diesel and calculating its instantaneous consumption is not so easy, there’s no direct flow sensor.

Fuel consumption may well be 30 tons per day. For 10 days of sailing — 300 tons. On this scale, 3 tons is just an error. However, 3 tons of fuel is $700–800, depending on the rates. We can calculate readings from several sensors, for this reason this solution is in demand.

...

The pivot wasn’t an easy decision. We had limited resources, little time and a very complex new product. We needed to design our equipment quickly, develop complex software and launch pilot projects.

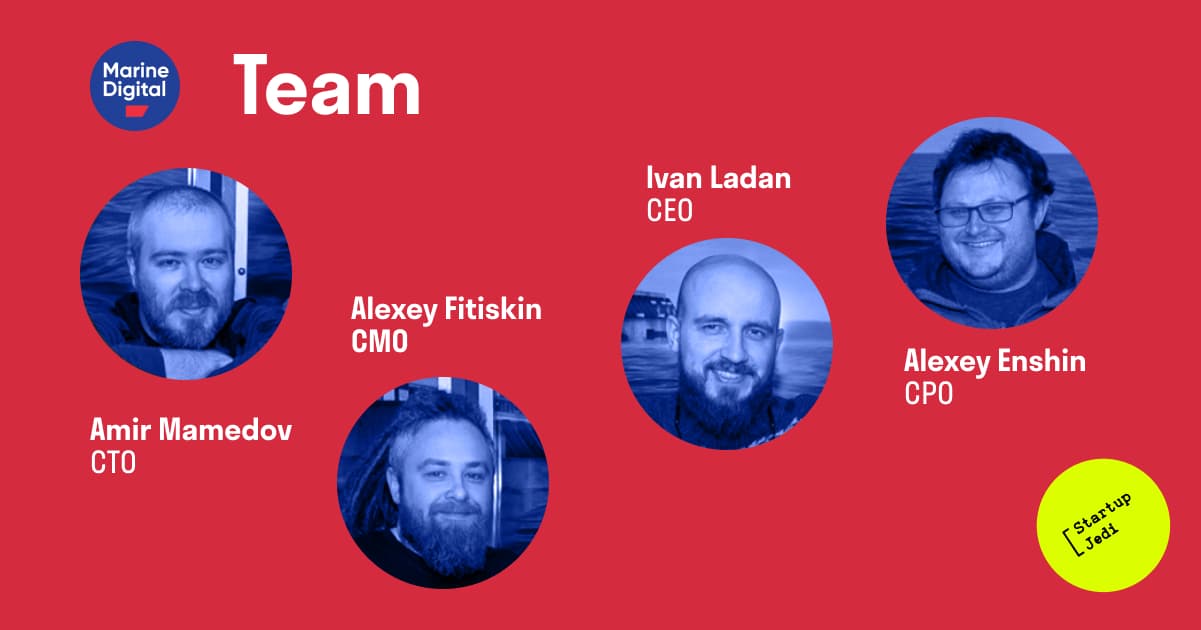

At that time, I made sure I had an amazing team. The principle of “hire people who are more competent than you” worked out all right: we coped with the tasks without unnecessary tension, excessive hours and quarrelling. It’s really pleasant to work in such a professional team without any “toxicity”.

Alexei Enshin, our CPO, is a former financial director of a shipping company that operated in the CIS and Baltic States. For more than five years he was working in Russian Railways. Amir Mamedov, our CTO, worked in Yandex and Wheely as a Lid developer. Alexey Fitiskin, the CMO, worked at ASoft, LANIT, My business, where he managed marketing, sales, partner programs and was in charge of different projects, including logistics automation. Dmitry Shusharin , the Head of Analytics, came to us with work experience in logistics projects at Alfa Bank and KMPG.

I was an investment director of the project on construction of logistics centers. Then I was involved in blockchain implementation in industrial structures, including logistics.

We understand that a startup cannot have all the necessary competencies at once, so we look for advisories regularly and strengthen our network. Our key advisors today are Alex Nelis, the owner of a medium-sized maritime agency company in the Netherlands, Konstantin Matveev and Alexey Sushilov from Marine Software Solutions in Latvia. They helped us to reach other stakeholders in the industry.

As a result, in the course of the year we pumped up our expertise strongly, took part in the final of the Competition in the Port of Rotterdam (Port XL accelerator), and participated in several industry exhibitions. At the beginning of this year we became partners of Novikontas Maritime College — the largest training center in the Baltic States. Thus we got access to a very large amount of engineering expertise.

...

We divide our competitors into three groups. Large companies with a client base of 500 ships or more fall into the first group. The second category is promising young technology teams that may quickly scale. The third group includes all the others that are somehow involved in digitalization in maritime logistics, such as the developers of route planning.

There are not many in the first group — about 10 companies. We keep an eye on them and their products. We have made a special more than 100 point checklist for product comparison and we regularly update it.

For example, Napa Auto Parts work under the wing of a major maritime engine manufacturer. BP invested in Green Steam. Their solutions make it possible to optimize fuel consumption. StormGeo offers a solution that makes routing fuel-efficient according to real-time weather conditions (NB: these companies have been operating for about 20 years and have been acquired by strategic investors).

We see the disadvantages of our major competitors and offer a comprehensive solution with a profitable cost. The price of our product is lower due to the lack of infrastructure costs, and the quality is increasing due to greater flexibility. We are faster in implementing new and more demanded solutions based on Customer Development.

According to estimates of industry publications there are about 500 startups in maritime logistics worldwide, while projects of our size in related niches are only a few. They are at about the same stages of attracting investment as we are.

Though the rate of digitization of the industry is increasing, the entry threshold is still high. A sales cycle is approximately 3–4 months, and it’s very fast. Without implemented projects, it is difficult for a startup to find partners at sea.

However we think it’s good for us. We have spent enough resources to get to this market. At the same time, large companies are trying to enter the market by buying startups and launching accelerators. So do Microsoft, IBM and other corporations. But compared to Fintech or any other advanced industry, the scale of this movement will be dozens of times lower.

We managed to get the first pilot projects thanks to the following principles. We offered our solution to as many potential customers as possible, didn’t get upset about rejections and kept working. All in all, everything worked out. We found companies with progressive executives who were interested in trying new solutions. We found enthusiasts from the funds. In addition, investment agencies in Finland and Estonia helped us a lot. They introduced us to the right people, and advised us on the events to visit. Thanks to these connections, we have structured a good partnership, which helps us a lot now.

...

Most of the merchant ships are registered in Greece. In total 40% of the world commercial fleet is concentrated in Europe. Another 45% in Asia, 5% in the United States and the rest in other countries.

There are more ports and terminals in Europe than in Russia. What’s more, most of them are private. So, we have chosen the European market targeting these two factors. In Russia, we simply don’t have an opportunity to implement pilot projects and make any progress.

We launched the company in Latvia and moved to Riga. Surprisingly, apart from common difficulties, we did not experience any special problems. Working in Europe is easier than working in Russia.

One of the advantages of the European market is that via LinkedIn you can contact the head of a large company, 2–3 out of 10 will reply to your message. It’s amazing after work experience in Russia. We use cold emails, I’ve written more than 500 of them. Industry events also work well and assist in finding new contacts, in Europe they are enough in offline and online formats.

State institutions also help. We are now attracting investments from Northern Germany, channeling funds for development and relocation there. It is very profitable for us, because there are many ship owners in the region. State investment agencies in Finland and the Baltic States have also helped with contacts and advice.

Cooperation with Axel Springer and Porsche has become for us noteworthy. We took part in their APX accelerator and got access to very cool industry expertise, and got acquainted with high-level mentors. Our startup has experienced an upswing in just a few months and we started to look at the product and market in a new way. Besides, the accelerator has also invested in us.

...

We have already raised investments from the European business angels and funds. By the end of the summer we’re planning to close the next round and collect €350 thousand. It’s important for us to find an investor with such experience that would correspond to challenges we are working with now: hardware manufacturing, last mile delivery, saas and distribution network scaling, AI.

Now we are actively communicating, monitoring the market, looking for relevant funds. When we won EMERGE CHALLENGE, Happag-Lloyd, the German largest shipping company, came to us and offered to take part in the acceleration program in Singapore. The Techstars team has also become interested in our startup, as they have a relevant fund.

...

The investments we have raised will help us to achieve three main goals. First, we’re planning to make our equipment as versatile as possible. Each ship uses its own systems, works its own cables and sensor connectors. Now we are making sure that our equipment can be installed on any ship in an hour without special training.

In the near future we will launch several more pilot projects to test our solution in different countries and on vessels of different types. Thus by round A we will have a clear vision of how to scale our solution.

The second Milestone is to reduce fuel consumption by 12% by using more accurate models. The third step is to double the number of customers and MRR. For this purpose we are going to build a partner network with better conditions than our competitors have, provide marketing support and prepare powerful marketing kits.

Facebook: facebook.com/StartupJedi/

Telegram: t.me/Startup_Jedi

Twitter: twitter.com/startup_jedi

Comments